Understanding the Role of Engine Parts Manufacturers

The automotive industry is a complex ecosystem that relies heavily on a multitude of suppliers and components to keep it running smoothly. Among these, engine parts manufacturers hold a pivotal position. These manufacturers are responsible for producing the essential components that power vehicles, ensuring their performance, safety, and longevity.

What Are Engine Parts Manufacturers?

Engine parts manufacturers specialize in the production of components vital for internal combustion engines and electric vehicle motors. These manufacturers create a diverse range of parts, including:

- Engine Blocks: The foundation of the engine that houses critical components.

- Cylinders: Where the fuel-air mixture combusts to produce power.

- Pistons: Moving components that convert fuel energy into mechanical work.

- Crankshafts: Vital for converting linear motion into rotational motion.

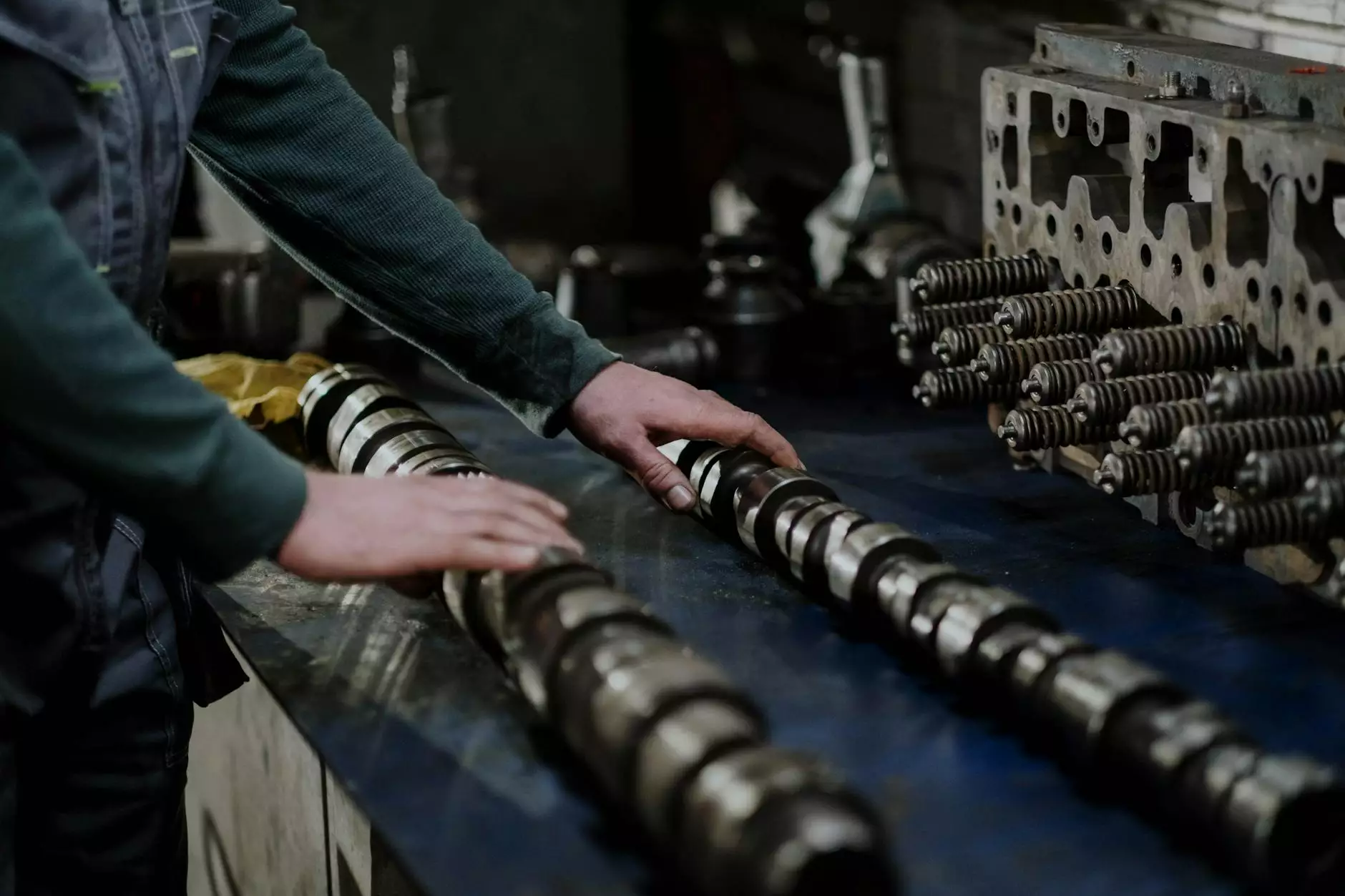

- Camshafts: Control the timing of the engine’s valves.

- Gaskets: Ensure there are no leaks between engine parts.

- Oil Pumps: Maintain lubrication within the engine.

The Importance of Quality in Engine Parts Manufacturing

Choosing the right engine parts manufacturers is crucial for the success of any automotive venture. High-quality parts directly influence:

Performance

The performance of a vehicle is directly linked to the quality of its engine components. For example, precision-manufactured pistons and crankshafts ensure smoother operation and higher efficiency. Quality parts contribute to better fuel efficiency and overall dynamics of the vehicle.

Safety

Safety is a non-negotiable in the automotive industry. Faulty engine parts can lead to catastrophic failures. Relying on reputable engine parts manufacturers helps minimize risks, ensuring that all components meet safety standards and regulations.

Longevity

Durability is another critical aspect. High-quality engine components are designed to withstand harsh operating conditions. This means fewer replacements over time, which is a significant cost-saving for businesses and consumers alike.

How to Choose a Reliable Engine Parts Manufacturer

When selecting an engine parts manufacturer, consider several factors to ensure you partner with the right entity. Here are key points to evaluate:

- Reputation: Research the manufacturer’s reputation in the market. Reviews and testimonials from previous clients can provide valuable insights.

- Certifications: Manufacturers should hold relevant certifications, such as ISO 9001, indicating they meet international quality management standards.

- Industry Experience: A manufacturer with a long history in the industry is likely to have the expertise required to deliver quality components.

- Technology: Assess the technology and equipment used by the manufacturer. Advanced machinery often results in higher precision and quality.

- Customer Service: Good communication and post-sale support are essential. Ensure the manufacturer is responsive to inquiries and supports their products.

- Customization Capability: Some projects may require tailored solutions. Check if the manufacturer can customize parts to fit specific needs.

Innovations in Engine Parts Manufacturing

The landscape of engine parts manufacturing is continually evolving, driven by technological advancements. Here are some of the exciting innovations shaping the future of engine component production:

3D Printing Technology

3D printing, or additive manufacturing, is revolutionizing the way engine components are produced. This technology allows for rapid prototyping and the creation of complex designs that were previously challenging or impossible to manufacture using traditional methods. Benefits include:

- Cost-Effectiveness: Reduced material waste and lower production costs.

- Customization: Easy adjustments to designs lead to tailored solutions for specific engine requirements.

- Speed: Faster production times from design to end product.

Lightweight Materials

Engine parts manufacturers are increasingly utilizing lightweight materials such as aluminum and carbon fiber. These materials provide strength while reducing overall vehicle weight, which contributes to greater fuel efficiency and better handling.

Smart Manufacturing

Integrating IoT (Internet of Things) technology allows manufacturers to gather real-time data throughout the production process. Smart manufacturing enhances quality control, improves production efficiency, and facilitates predictive maintenance, ultimately leading to higher-quality engine components.

The Global Impact of Engine Parts Manufacturers

The influence of engine parts manufacturers extends far beyond the automotive industry. Their operations support various sectors, including:

Aerospace

Many principles of engine design and manufacturing are applicable in aerospace. The demand for lightweight, high-performance parts is a driving force for innovations in both industries.

Marine Applications

Marine engines, especially for boats and ships, utilize critical components produced by specialized engine parts manufacturers. The maritime industry benefits from collaboration with experienced automotive suppliers.

Industrial Machinery

Engines are pivotal in industrial machinery, including construction and agricultural equipment. The expertise gained in automotive engine parts manufacturing is leveraged to improve machinery performance.

Challenges Facing Engine Parts Manufacturers

Despite their importance, engine parts manufacturers face several challenges, including:

- Supply Chain Disruptions: Global events can impact the supply of raw materials, leading to production delays.

- Regulatory Compliance: Adhering to stringent regulations regarding emissions and safety can increase manufacturing complexity.

- Technological Advancements: Keeping up with fast-paced technological changes requires continuous investment in R&D.

Future Trends in Engine Parts Manufacturing

The future of engine parts manufacturing is anticipated to be influenced by several key trends, including:

Increased Focus on Sustainability

As environmental concerns grow, manufacturers will need to focus on sustainability in their production processes. This includes using environmentally friendly materials, reducing emissions, and improving energy efficiency in manufacturing operations.

Electrification of Vehicles

With the rise of electric vehicles, traditional engine parts manufacturing is set to evolve. Manufacturers must adapt by developing components for electric drivetrains and related technologies.

Conclusion

In conclusion, engine parts manufacturers play a vital role in the automotive industry and beyond. Their dedication to producing high-quality components ensures not only the performance and durability of vehicles but also their safety. As the industry evolves with technology and sustainability challenges, these manufacturers are at the forefront of innovation, driving the future of transportation and machinery.

By choosing the right partners, such as those listed on imautoparts.com, businesses can ensure they are equipped with the best engine components available, enhancing their products' efficacy and reliability.