The Advantages of China Rapid Prototyper in Modern Manufacturing

Business leaders and innovators are continually seeking ways to improve their manufacturing processes, and utilizing a China rapid prototyper represents one such transformative approach. In this article, we’ll delve deep into the multifaceted benefits that these prototyping technologies bring to the table, particularly in the sphere of metal fabrication.

What is Rapid Prototyping?

Rapid prototyping is an innovative manufacturing process that allows for quick and cost-effective creation of prototypes from 3D computer-aided design (CAD) models. It emphasizes speed, allowing businesses to rapidly iterate on designs, which can subsequently lead to better final products.

The Rise of Chinese Rapid Prototypers

In recent years, Chinese manufacturers have established themselves as leaders in the field of rapid prototyping. Here are some key reasons why:

- Advanced Technology: China has invested significantly in cutting-edge manufacturing systems, allowing for high-quality prototypes in various materials.

- Cost Efficiency: Due to lower operational costs, Chinese rapid prototypers can offer competitive pricing without compromising quality.

- Scalability: Many Chinese manufacturers can easily ramp up production as demand increases, making them a preferable choice for businesses looking to scale quickly.

Benefits of Using a China Rapid Prototyper

1. Cost-Effectiveness

One of the most compelling advantages of utilizing a China rapid prototyper is the significant cost savings that can be achieved. Companies can avoid hefty expenses typically associated with traditional prototyping methods. Each prototype can be produced at a fraction of the cost, enabling businesses to explore multiple design options without breaking the bank.

2. Speed of Production

Time is a precious commodity in the world of business. The rapid production capabilities offered by a China rapid prototyper facilitate faster turnaround times, allowing companies to get their products to market sooner. This speed is essential in staying ahead of competitors and satisfying customer demand swiftly.

3. Precision and Quality

Modern rapid prototyping techniques, such as SLS (Selective Laser Sintering) and SLA (Stereolithography), allow for highly precise and intricate designs. The quality standards maintained by Chinese manufacturers ensure that the prototypes are not only accurate representations of the envisioned product but also capable of withstanding rigorous testing.

4. Flexibility in Design

Rapid prototyping fosters an environment of innovation. Designers can experiment with new ideas rapidly and can make adjustments based on real-time feedback. This flexibility is crucial in an era where consumer preferences can shift quickly.

5. Environmental Benefits

Using a rapid prototyping approach reduces material waste. Traditional manufacturing often results in a higher rate of waste; however, with additive manufacturing processes, only the necessary amount of material is used, which can lead to a more sustainable business model.

Applications of Rapid Prototyping in Metal Fabrication

The metal fabrication industry has embraced rapid prototyping, leveraging it to streamline operations and enhance product offerings. Here’s how:

1. Automotive Industry

Automakers use rapid prototyping to create prototypes of components such as gears, brackets, and interior panels. This expedited process allows them to test various design iterations before mass production, ultimately leading to improved efficiency and quality.

2. Aerospace Sector

The aerospace industry requires components that are not only lightweight but also incredibly strong. Utilizing China rapid prototyping technology, manufacturers can produce complex parts that meet stringent regulatory standards while optimizing weight and material use.

3. Medical Devices

Rapid prototyping plays a vital role in developing medical devices, from surgical instruments to prosthetics. The precision and customization capabilities offered allow for the creation of tailored solutions that meet specific patient needs.

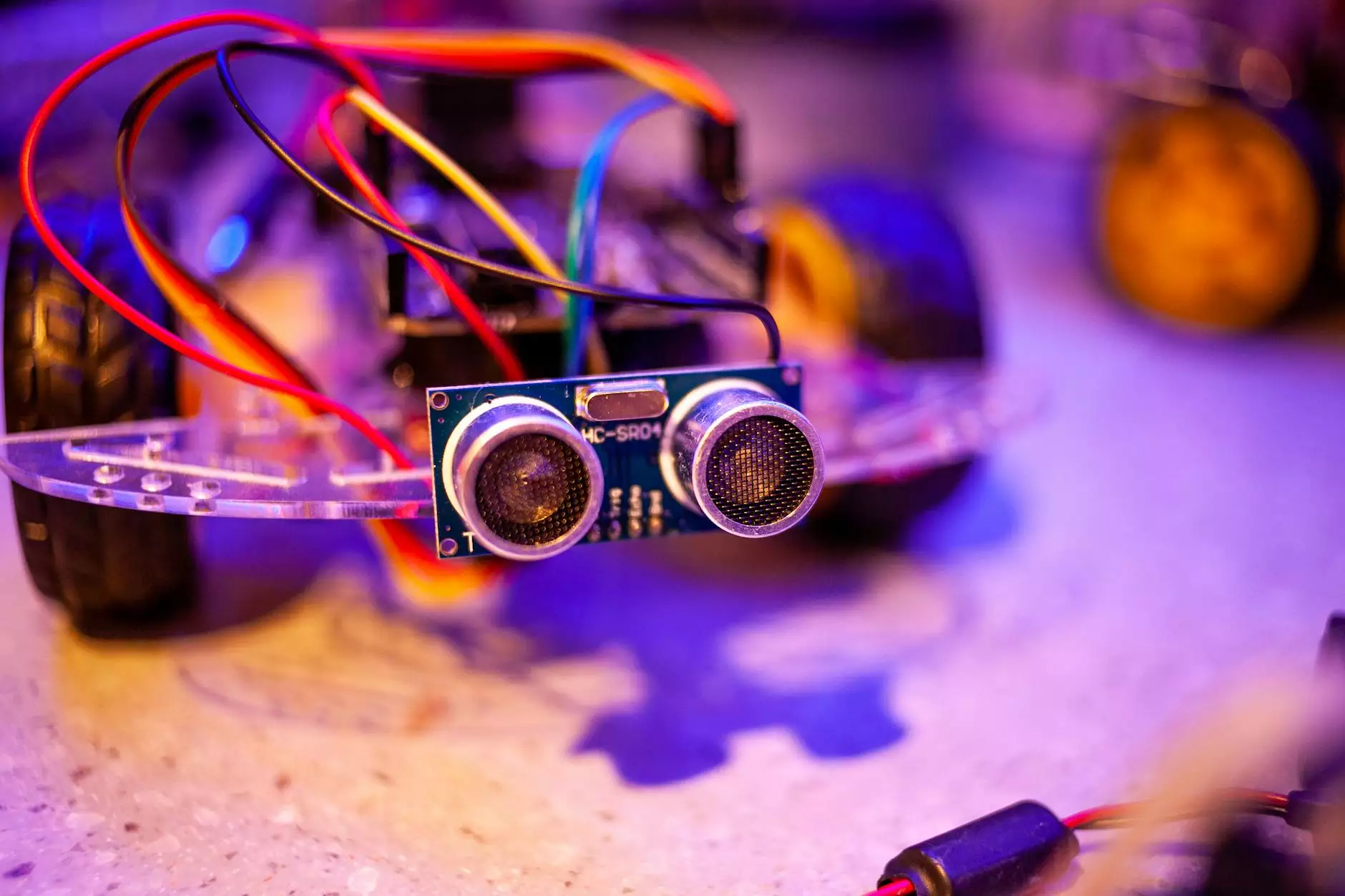

4. Electronics

In the electronics field, rapid prototyping enables engineers to develop and test circuit boards and housings quickly. By running multiple design scenarios in rapid succession, firms can align their offerings with technological advancements and market demands.

Key Technologies Behind Rapid Prototyping

Several technologies underpin the rapid prototyping process. Understanding these can give businesses valuable insights into which methods might be best suited to their needs.

1. Stereolithography (SLA)

SLA involves using a laser to solidify liquid resin layer by layer. It is known for producing high-fidelity prototypes with exceptional surface finishes, making it ideal for product visualization.

2. Selective Laser Sintering (SLS)

SLS uses a laser to sinter powdered material, typically plastic or metal, into solid structures. This method is excellent for creating functional parts that can endure real-world use, providing unparalleled flexibility in material choice.

3. Fused Deposition Modeling (FDM)

FDM works by extruding melted thermoplastic in layers. This widely-used method is accessible and cost-effective, particularly for prototyping larger items.

4. Digital Light Processing (DLP)

Similar to SLA, DLP employs light projected onto a photosensitive resin but does so much faster by curing an entire layer at once. It strikes a balance between speed and detail.

Choosing the Right China Rapid Prototyper

When selecting a China rapid prototyper for your business, it is essential to consider the following factors:

- Capabilities: Assess the technology and materials they can work with.

- Experience: Look for a provider with a proven track record in your industry.

- Quality Assurance: Ensure they follow stringent quality control protocols.

- Customer Support: Choose a partner that provides dedicated support throughout the process.

- Delivery Times: Confirm they can meet your scheduling needs.

Future Trends in Rapid Prototyping

The landscape of rapid prototyping continues to evolve, with several exciting trends on the horizon:

- Increased Automation: Automation will reduce manual handling and errors, paving the way for more streamlined operations.

- Integration of AI: AI can optimize design processes and predict potential flaws before they arise.

- Materials Advancements: New materials will enhance the performance and applications of prototypes, allowing for stronger and lighter products.

- Eco-Friendly Materials: With a growing emphasis on sustainability, more companies will develop biodegradable printing materials.

Conclusion

The integration of a China rapid prototyper into your manufacturing process can lead to transformative benefits, ranging from cost savings to increased production speed and design flexibility. As the landscape of manufacturing continues to evolve, embracing rapid prototyping is no longer just an option—it is a necessity for businesses looking to stay competitive in today’s market.

At Deep Mould, we are committed to helping you navigate the evolving manufacturing landscape. Our extensive experience in metal fabrication, combined with advanced rapid prototyping technologies, positions us as your ideal partner for taking your business to the next level. Contact us today to learn more about how we can assist you in leveraging rapid prototyping for your next project.